Energy harvesting using thermophotovoltaics

From 20 to 50% of industrial energy consumption is wasted in the form of heat. This heat can be found in the form of solids, liquids and gases at different temperatures ranging from a few tens to several hundreds of ºC. At IES, we are developing infrared sensitive photovoltaic cells, so-called thermophotovoltaic (TPV) cells, to convert the ultra high temperature (>800ºC) waste heat into electricity. A TPV cell works in exactly the same way as a solar cell: the absorption of photons into a semiconductor material produces electrons that is supplied outwards creating an electric current. The difference lies in the absorption spectrum that in a TPV cell is moved towards the infrared to efficiently convert thermal radiation instead of solar radiation.For this semiconductor materials are used that can absorb low energy photons, such as the germanium or gallium antimonide, instead of semiconductors that efficiently absorb sunlight such as silicon or gallium arsenide. |

|

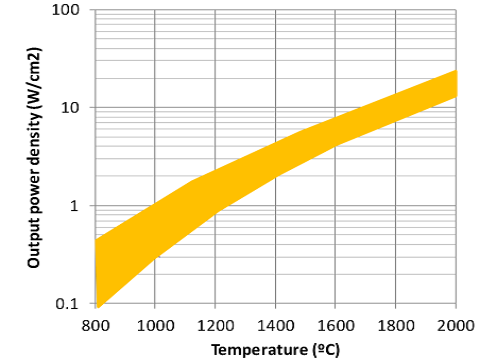

| In general, a TPV cell works with thermal sources that exceed 800°C and their conversion efficiency to date is in the region of 20%. In addition, they can generate very high electrical power densities of more than 1 W/cm2, in other words around 50 times more than conventional solar cells. This means that competitive per unit power costs (in €/W) can be achieved. However, TPV technology is still in a very early phase of development and there is much room for improvement: power efficiencies and densities of more than 40% and 10 W/m2, respectively, could be achieved. The improvement potential in the efficiency of these devices stems from the ability to adjust the emission spectrum of the thermal source to the spectral response of the cell, something that is impossible in a solar cell. |  |

|

This could be undertaken by using filters or mirrors to return the part of the spectrum not absorbed in the cell to the thermal source, so that this radiation is reabsorbed with no consequent energy loss. An alternative option is developing multijunction TPV devices. As such, on paper, it would possible to achieve conversion efficiencies of more than 50%. TPV solutions for waste heat recovery applications focus on very high temperature industries, in which process temperature exceeds 800ºC. Particularly relevant industries due to their production volume are: steel (1,600 Mton/year), glass (52 Mton/year), ferrosilicon (7.4 Mton/year) and silicon (1.8 Mton/y).

Contact person: Dr. Alejandro Datas

Selected publications A. Datas, "Energía termofotovoltaica: la conversión fotovoltaica del calor y su aplicación en sistemas de almacenamiento de energía", FuturENERGY, pp. 1-3, 2015. |

|