1. Manufacturing of silicon solar cells

- Dicing saw for wafers and glass substrates, model DISCO DAD321 for round (6”) and square wafers (156x156mm). Cut resolution of 1µm and a maximum stroke length of 32mm.

- Wet benches. Etching, texturing and cleaning available for 2” and 4” wafers.

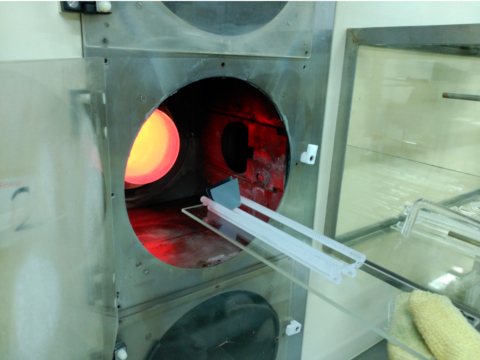

- Diffusion furnaces. 6 furnaces for doping (P and B), oxidation and annealing wafers up to 4”.

- PECVD reactor. Plasma enhanced chemical vapor deposition of silicon nitride coatings. Up to 4” wafers.

- Photolithography mask aligner for 2’’ wafers

- Physical Vapor Deposition Equipment. E-gun and Joule-effect evaporation. Ti, Pd, Ag, Al. Up to to 4” wafers

|

|

|

2. Manufacturing of multijunction and advanced solar cells

- Cleaning and etching wet benches: acids, organics, plasma asher, contact layer etching, mesa etching

- Photolithography Mask aligner - SUSS MicroTec MJB4. High-resolution photolithography in substrates and wafers up to 4''/ 100mm.

- Wirebonder DELVOTEK 5430. Equipment to make aluminum/gold wire connections with 17.5 to 75 um diameter.

- Electron Beam Physical Vapor Deposition Tool- Classic 500 Twin High Vacuum Coating System. Separate chambers for metal and dielectric coatings

- Joule effect Physical Vapor Deposition Tool for metals- Telstar Vacudel 300

- Joule effect Physical Vapor Deposition tool for dielectrics

- Rapid Thermal Process (RTP). Wafers up to 6’’; maximum heat slope of 75 K/s and temperatures up to 1000 °C; Anneal atmospheres available: Nitrogen, Hydrogen and Forming.

- Plasma asher. Low pressure plasma system from DIENER ELCTRONIC to clean semiconductor wafers.

- Sputtering system to produce thin films. PVD-MT/2M3T equipped with two sputtering RF magnetrons and three resistive thermal evaporation sources in the same process chamber.

Official rates for these services can be found at UPM WEB SITE. |

|

|